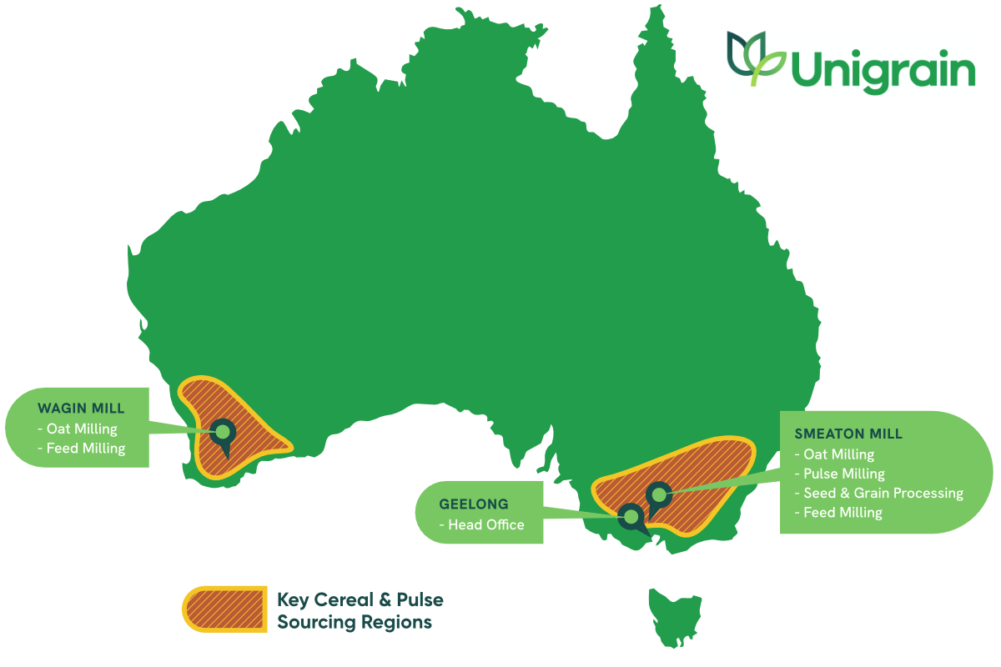

GEELONG, VICTORIA, AUSTRALIA — Oat and pulse processor Unigrain has unveiled plans to build a new pulse fractionation facility at its cereal and pulse milling site at Smeaton, Victoria, Australia.

According to Unigrain, the facility will have the capability to produce a range of plant-based food ingredients, with the initial key focus on pea and fava bean protein concentrates, which have a wide range of food-based applications in Australia, most notably within the bakery, snacks and cereals, and plant-based meat sectors. Once completed, the facility will be the first fully integrated pulse milling and fractionation process in Australia, and the first to utilize dry protein extraction technology that is being designed and engineered in Germany, Unigrain said.

“Manufactured from locally grown pulses without the aid of water or chemical treatment, we are particularly proud of the high benchmark we are looking to set for the environmental sustainability of our products,” said Fiona May, co-chief executive officer of Unigrain.

Unigrain said it initially plans to process more than 40,000 tonnes of field peas and fava beans per year at the site, with the ability to increase capacity as the market continues to grow.

“Consumers are increasingly turning to pulse-based proteins as part of a broader emphasis on health, lifestyle and the environment,” said Andrew May, co-chief executive officer. “We are thrilled to be a part of Australia’s journey in the alterative protein sector and help facilitate the development of the Australian supply chain.”

May said work also is underway to develop a broader range of fractionated cereal and pulse products into the future, including across lentils, chickpeas and oats.

Construction of the facility is set to commence in early 2022 with full scale production set to be underway in mid-2022.