Slideshows

Al-Hazaa expands with second flour mill in Egypt

The facility is located in the same industrial area in 6th of October City, Egypt, as its first mill.

Seaboard builds new mill in Zambia

Greenfield facility in Lusaka nearly triples its daily flour production capacity.

NAMA gathers in Colorado Springs for annual meeting

The North American Millers’ Association held its 2019 annual meeting at The Broadmoor in Colorado Springs on Oct. 17-20.

ADM new feed mill promises efficiency

Facility in Quincy, Illinois, U.S., combines feed lines from a large footprint into one 8-story building.

New grain facilities, expansions take off in North America

Region continues to see growth despite concerns over ongoing trade disputes.

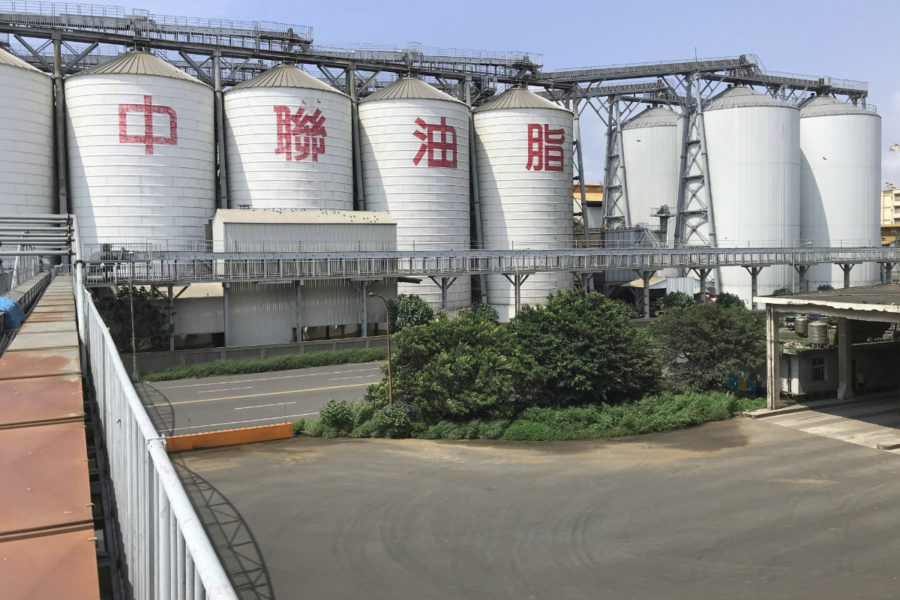

Southeast Asia bustling with grain storage, handling projects

Suppliers completed multiple expansions and new facilities in the region recently.

Major grain projects completed throughout Europe

They included a grain collection point in Germany and a new cooperative facility in Latvia.

GEAPS 2019

407 exhibitors displayed the latest products and services for the grain industry at the 2019 GEAPS Exchange in New Orleans, Louisiana, U.S.

IPPE 2019 attracts record turnout

A record 33,000 delegates attended this year’s IPPE along with more than 1,420 exhibitors.