KANSAS CITY, MISSOURI, US — Storage and handling systems for large quantities of grain and more safety features are two of the top concerns for the industry, said bin manufacturers participating in the Grain Elevator and Processing Society’s (GEAPS) Exchange 2024.

The event in Kansas City, Missouri, US, continues to Feb. 27.

“Everybody is going for bigger grain bins,” said Casper Cronjé, farm grain systems, sales manager, Sioux Steel Co. “The storage facilities get bigger and bigger every year.”

The 1-million-bushel-plus bins are popular in the United States where large quantities of grain are produced and turned over at a high rate, said Travys Woodside, vice president of international sales, Chief Agri.

One of the biggest challenges with the larger bins is keeping the grain in condition, Woodside said.

“Aeration is so important; we focus on that first,” he said. “We design the silo around making sure that the aeration will function and have adequate air flow.”

Credit: ©SOSLAND PUBLISHING CO.

Credit: ©SOSLAND PUBLISHING CO.Yields keep increasing, so there’s a need for more storage, said Brent Hansen, commercial accounts manager, Sukup Mfg. Co.

“Some of these facilities are getting older and tired,” he said. “Everything is bigger and faster. It used to be 10,000 bph was a decent size. Now we see receiving of 20,000 to 30,000 bph.”

Some customers have switched to bins from piles and fabricated buildings.

“The labor to reclaim grain out of those is substantially more than in the bin,” he said. “It’s easier to keep the grain in condition. We see some of these cooperatives trying to get down to a single man operation. With less labor force, they need more automation.”

John Messner, territory sales manager for AGI, said a popular bin size in the last eight years has been 78-feet in diameter and 19 tiers high (each tier is 44 inches). The company has sold at least 60 of them in Canada in that timeframe, he said.

Credit: ©SOSLAND PUBLISHING CO.

Credit: ©SOSLAND PUBLISHING CO.“It seems to be the sweet spot bin for price and storage capacity needed,” Messner said, adding that the company also offers larger diameter bins, up to 135-feet, which have been sold in the United States.

Messner said he has also noticed an increase in quotes for hopper bins, from about 20% to 25% of business to 45% to 50%.

“I think the reason is the natural discharge into conveyors,” Messner said. “You don’t need bin sweeps and there’s less moving parts.”

AGI highlighted the sensor technology it has available to monitor conditions such as temperature and vibration on handling equipment, ensuring safe operation.

Safety is a continuing concern for all customers. Hansen said Sukup’s paddle sweep has become popular because of its safety compared to an auger sweep.

“The main thing is pay attention to your bin monitoring equipment,” he said. “When you see something, react quickly; don’t wait. Keeping grain in condition is one of the biggest safety factors. If you keep grain in condition, there’s no reason to go inside bins.”

Credit: ©SOSLAND PUBLISHING CO.

Credit: ©SOSLAND PUBLISHING CO.Brock Grain Systems was showcasing its TrueGrain moisture sensor system that helps ensure grain comes into a bin in good condition and stays that way. It is a more consistent and accurate way to direct grain flows to dryers and measure grain moisture.

In a traditional drying system, grain flows across horizontally mounted sensors. The problem is there is variable depth and other conditions can interfere with measurements, said Tim Stinson, business development manager, Brock Grain Systems.

With TrueGrain, a precise volume of grain passes through a parallel sensing field in a vertical sensor chamber.

“Since you have twin sensors and a metering wheel, it keeps the chamber full of a consistent amount of grain, so you get a much more accurate reading,” Stinson said.

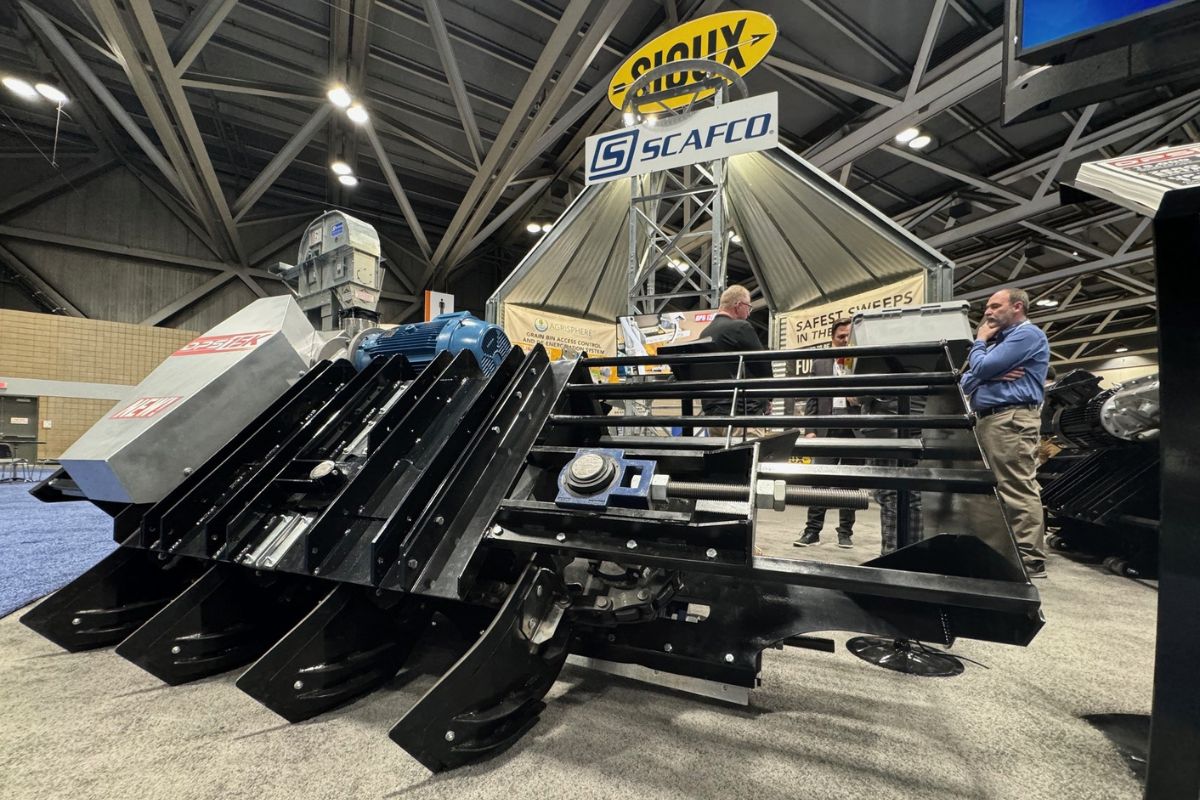

Sioux Steel was showcasing its new 10K paddle sweep for bins up to 132-feet at a capacity of 10,000 bph and its 15K paddle sweep for bins up to 162 feet in diameter and a capacity of 15,000 bph.

Credit: ©SOSLAND PUBLISHING CO.

Credit: ©SOSLAND PUBLISHING CO.“It’s a new design and new format,” Cronjé said. “We’re excited to get it out in the field.”

The paddle sweeps will be available in North America first and will expand into an international market, he said.

Business is strong on the feed and processing side, said Chief’s Woodside, especially byproducts of soybean crushing.

“We’ve seen a lot more requests of how do we handle soybean meal, how do we store it and how do we take care f this product that’s pretty tough to handle?” he said. “We’ve got a few things that we’re working on right now to be able to do that.”

With a number of soybean crushing facilities planned, in large part to meet the demand of biofuels, there will be opportunities for more storage and handling. In Southeast Asia, there is also strong demand for soybean oil for human consumption and feed.

The region, along with Africa, are two areas that are seeing some of the biggest growth overall, Woodside said.

“These smaller countries are starting to invest in food bank programs and long-term food storage,” he said. “There’s a lot more commercial infrastructure that has to be built in order for that to happen.”

Grain prices, which have been returning to more normal levels, do impact business, several storage and handling companies said. But the impact is usually more pronounced on the farm side. It also depends on the market, Woodside said.

“When international prices are down, that means trading gets better and we see more investment in port facilities,” he said.