The tortilla has found its way onto supermarket shelves around the globe. In the United States, in particular, this product has long been a constant among baked foods and is an indispensable part of popular Mexican cuisine.

Originally, the tortilla was the staple food of the ancient Aztecs in Mexico. They had made flat cakes from corn (maize) for centuries, calling them “tlaxcalli,” a native word that the Spanish settlers adapted into their own language as “tortilla.”

The tortilla initially was made from corn, but with the arrival of the Spanish and the production of wheat flour, tortillas began to be made from flour and are now generally known by the name wheat flour tortillas, or simply flour tortillas.

Importance of tortillas in the market

While the popularity of the tortilla is growing globally, the North American region is seeing the fastest growth rate within this bakery segment, reports Future Market Insights. In the United States, there are approximately 200 tortilla facilities, most of them members of the Tortilla Industry Association (TIA). The whole category — including wheat flour and corn tortillas, tortilla chips, tacos, tostadas and salsas — generates sales of approximately $25 billion and shows a growth rate of 5%.

This development is driven by the growing Hispanic population in the United States. The local presence of major tortilla producers is further pushing the expansion of the industry.

Apart from that, the tortilla is popular with North American consumers due to its versatility. It may be used to create various dishes like tacos, fajitas, burritos and quesadillas — familiar from Mexican cuisine. Apart from traditional dishes, they also are enjoyed as wraps with all kinds of fillings ranging from salad and vegetables to fish and meat options.

Ingredients for the perfect tortilla

Tortillas are a single-layered flatbread. Unlike in Mexico, there is a clear preference for flour over corn tortillas in the United States. Flour tortillas generally are made from hard or soft wheat flour, although recipes with whole wheat flour, composite flours and gluten-free flours are gaining popularity, mostly because of the rising demand for products with health claims.

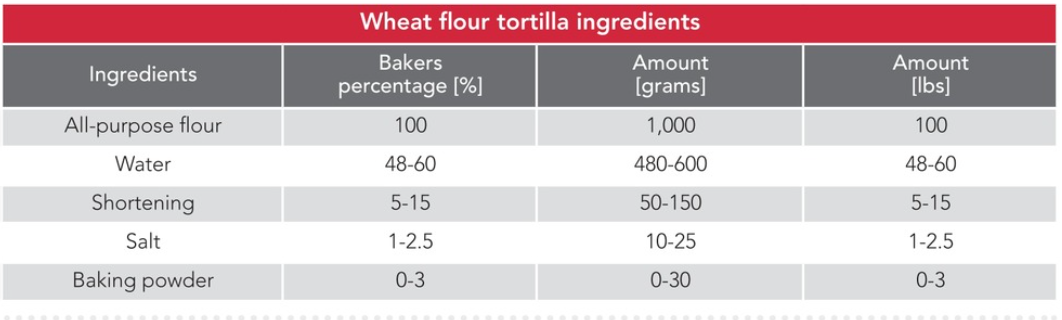

A common flour tortilla is prepared from wheat flour, shortening, water and salt, although baking powder or yeast also are used in some recipes. The following is a typical recipe:

- High-quality flour tortillas should be:

- Soft and flexible to allow rolling or folding without cracking throughout the shelf-life

- Symmetrical and uniform in size

- Opaque, with toasted spots

- Pleasant in taste

- They should have:

- A consistent diameter suitable for the

- intended use

- A shelf-life of up to six months

Industrial production of tortillas takes place in two different processes. Hot-pressed tortillas are the industry standard. Their main characteristics are slight off-roundness, elasticity, a smooth surface, and resistance to tearing and moisture absorption from fillings. The die-cut process mainly is used to produce corn tortillas, but it can also be used in flour tortilla production.

Some flour tortillas made with this process have a dusting of flour on the surface and are used in frozen Mexican foods and fried products. During the production process, the key quality attributes that lead to the desired functionality of tortillas are extensibility during pressing (diameter) and retention of flexibility over time (shelf stability). Commercially produced flour tortillas have a shelf-life of up to six months, which can be improved by the use of additives in the recipe.

Credit: ©MÜHLENCHEMIE

Credit: ©MÜHLENCHEMIE

Production process of tortilla

The recipe for flour tortillas is simple, consisting of wheat flour, shortening, salt and water. Tortillas of better quality are prepared mainly from hard wheat flour with a medium protein content. Hard wheat flour is preferred in industrial production. However, soft wheat flour may also be used, particularly when the product is made at home.

In the industrial manufacture of wheat tortillas, first ingredients are weighed out and the dough prepared. After mixing, the dough is rested for 5 minutes, then cut and shaped into balls of approximately 15 to 60 grams each with the help of a rounding machine. These dough pieces are allowed to rest for 10 to 15 minutes, then pressed into disks with hot plates set to 200°C to 230°C (392°F to 446°F) (hot press process). Since both thick and thin versions of this product are consumed, thickness ranges from 0.2 to 0.5 cm.

Tortillas are baked industrially in a conveyor oven at approximately 190°C to 220°C (374°F to 428°F) for 20 to 30 seconds and flipped multiple times. In small-scale production, the process takes place on a hot griddle or hot plate at approximately 200°C (392°F). When the tortilla puffs (after 15 to 20 seconds, depending on its thickness) it is flipped to bake the other side for 10 to 15 seconds. Finally, it is cooled and packaged.

Recommendations for best results

Here is a list of the most common challenges encountered in tortilla production, and how to avoid them:

Problem: Sticky dough.

Possible causes: Prolonged mixing and resting; high amylolytic activity; high dough temperature; low-fat formulation.

Solutions: Reduce mixing and resting time; use flour with low enzymatic activity (high Falling Number); reduce the addition of amylolytic enzymes (if any), add enzymes for anti-sticking (e.g. Alphamalt Gloxy TGO); check the water temperature frequently; add fat to the recipe; use glycerides or other emulsifiers (e.g. Mulgaprime 90F, Mulgaprime SSL).

Problem: Poor machinability of the dough.

Possible causes: Addition of an inappropriate amount of water (more or less than required); with weak wheat flour, low gluten content and high tenacity; with strong flour and high gluten content.

Solutions: Choose the best flour, with special emphasis on its rheological characteristics; use more water in the recipe; incorporate shortening, emulsifiers such as monoglycerides (e.g. Mulgaprime 90F) or lipases (e.g. Alphamalt EFX Tera) to improve dough machinability; for weak flour: incorporate oxidizing agents like ascorbic acid (Elco P-100) or azodicarbonamide (OXEM) or oxidizing enzymes (e.g. Alphamalt Gloxy TGO) to strengthen the dough; for strong flour: use dough softeners like cysteine (e.g. MCsoft S) or enzyme-based solutions (e.g. MC T-REX); adjust mixing and resting times.

Problem: Drying and staling of tortillas

Possible causes: Dough too firm; low water retention; starch retrogradation; use of thermosensitive amylolytic enzymes.

Solutions: Add water and emulsifying agents to improve the softness of the dough (e.g. Mulgaprime SSL); use hydrocolloids like guar gum (e.g. MCgum) to facilitate water retention; use moderately thermostable amylolytic enzymes (e.g. Flexizym Plus).

Problem: Short shelf life (microbial); tortillas are decomposed rapidly by microorganisms.

Possible causes: pH of the product 6.5 or higher; high microbial numbers in the process environment.

Solutions: Adjust the pH with acidifying agents (e.g. MCprop G) and control the addition of leavening powder; check hygiene conditions and sanitation in the production area; use air filters in particular for ventilation of the packaging area; produce per GMP; add preservatives such as propionate (e.g. MCprop P).

Problem: The tortillas are not inflated.

Possible causes: Insufficient mixing and resting time; too little leavening agent and/ or yeast; strong wheat flour, high tenacity.

Solutions: Increase mixing and resting time; add a larger proportion of leavening agents and/or yeast (e.g. MCrise SD); use reducing agents that facilitate the extensibility of the dough (e.g. MCsoft S).

Problem: Dark tortillas

Possible causes: High pigmentation of the wheat; high content of phenols and phenol oxidase.

Solutions: Use different wheats; standardize processes and flour milling; use improvers to brighten the color of the tortillas.

Problem: Color variation of flour tortillas.

Possible causes: Use of flour from wheat of varying quality; changes in the flour production process.

Solutions: Use wheats with similar characteristics; standardize processes and flour milling; use improvers to standardize the tortilla color

Sven Mattutat is a product manager with Mühlenchemie. He may be reached at [email protected] for more information on this topic.