PLYMOUTH, MINNESOTA, US — Bühler is expanding its optical sorting testing and applications capabilities in North America with new locations and centers.

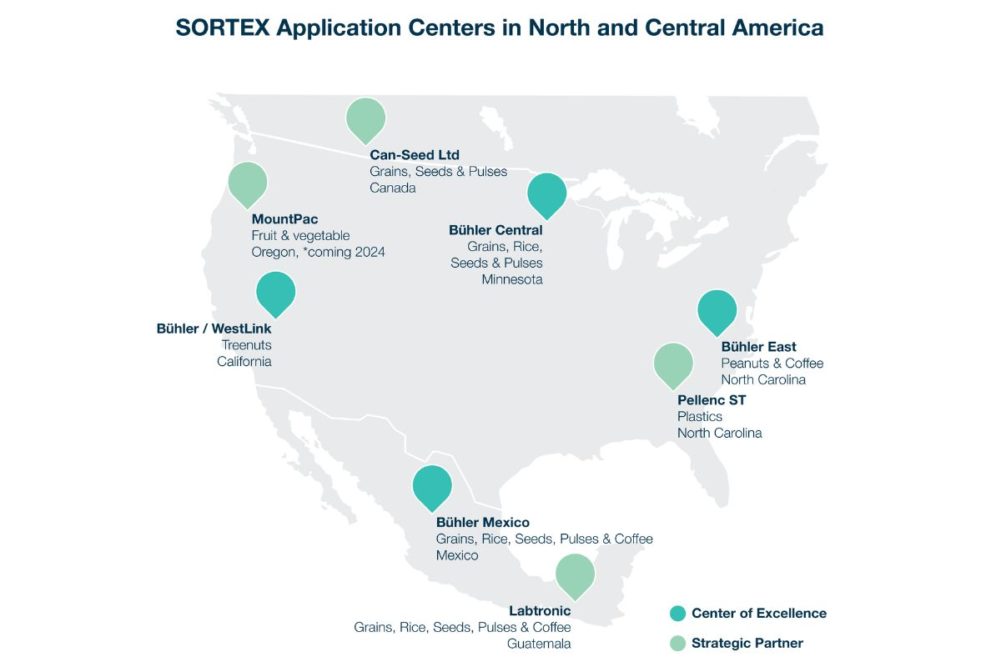

The expansion includes a new location for the current Stockton, California, US, lab and new centers in Cary and Charlotte, North Carolina, US; Plymouth, Minnesota, US; and Saskatoon, Saskatchewan, Canada.

The new centers join existing labs in Temecula, Mexico and Guatemala. All application centers also will act as training centers for the company’s various sorting solutions.

The application center in Stockton, California, focused on the tree nut market, will be moving to a new shared location, still in Stockton, with Bühler’s West Coast channel partner, West-Link. The new lab space will contain several current sorting platforms as well as the new Sortex H with MerlinAI. This location also will feature the new Sortex N with ColorCam+ and InGaAs HD for next-level shape detection.

New application capabilities for nut sorting will be added to the Cary drying application center while the new location in Charlotte will focus on the plastics recycling industry. The center will be hosted by Pellenc ST, Bühler’s channel partner for the plastics recycling industry.

The recently opened Food Application Center will provide a range of sorting capabilities focused mainly on the wheat and rye milling industries, along with optical sorting for all types of agricultural seeds and specialty milling applications, including pulses, corn, oats, and ancient gains. These capabilities also will be supported by Can-Seed, Bühler’s Canadian channel partner in their facility located in Saskatoon, Canada.

The existing application centers in Temecula, Mexico and Guatemala provide optical sorting testing and training for grains, rice, seeds, pulses, and coffee for their respective regions.

“The expansion of these capabilities will make it more convenient for processors across a number of industries in North America to test our different optical sorting capabilities,” said Laurenz Bay, head of sales for Bühler’s Digital Technologies. “By having access to a greater testing footprint along with our industry-leading process knowledge, our customers can more quickly perfect their processes and bring their products to market.”