ISTANBUL, TURKEY — Alapala Group has commissioned a collaborative robot (cobot) in its manufacturing plant.

Equipped with artificial intelligence-based technologies, cobots are different from traditional industrial robots with their ability to work with people in close proximity.

Alapala’s manufacturing plant has been equipped with advanced production technologies including robotic welding, bending, and automated painting systems. The new cobot started its operation in June.

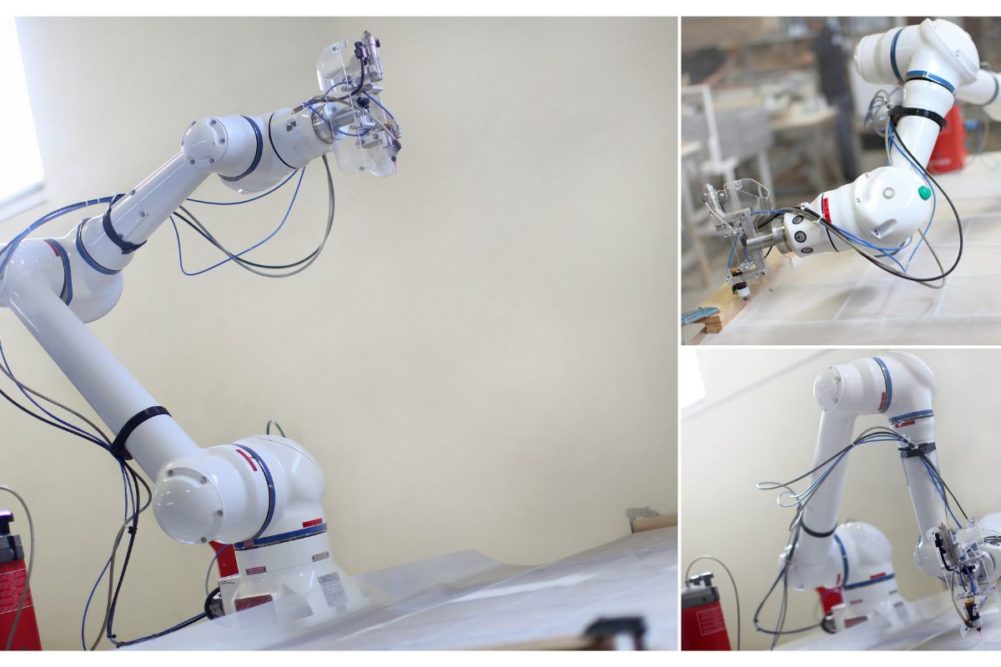

The cobot has 12 different sensors that perceive any close interaction, enabling the cobot to work with employees at the same working environment. Operator’s safety also is assured by “Power and Force Limit” technology that stops the cobot in case of any possible contact with employees. The 6-axis movement ability of the cobot also provides a very high precision and conformity for a wide variety of applications.

Gorkem Suner, general manager of Alapala Machinery Inc., said this was the first cobot project in the plant, and will be followed by other cobot installations soon to be adapted for different duties in production.