Animal feeds play a leading role in the global food industry, enabling the economical production of products of animal origin throughout the world. They may be produced in industrial feed mills or in simple on-farm mixers. Manufactured feeds are used to grow or maintain animals for food, fiber and other products under a wide range of farming conditions.

Mycotoxins are naturally occurring toxins produced by certain molds (fungi) and can be found in food. The molds grow on a variety of different crops and foodstuffs, including cereals, nuts, spices, dried fruits, apples and coffee beans, often under warm and humid conditions. Mycotoxins can cause a variety of adverse health effects and pose a serious health threat to both humans and livestock. The adverse health effects of mycotoxins range from acute poisoning to long-term effects such as immune deficiency and cancer.

It is important to note that mold that produces mycotoxins can grow on a variety of different crops and foodstuffs and can penetrate deep into the food and do not just grow on the surface. Mold usually does not grow in properly dried and stored foods, so efficient drying of commodities and maintenance of the dry state, or proper storage, is an effective measure against mold growth and the production of mycotoxins.

Wayne L. Bryden, PhD, The University of Queensland, School of Agriculture and Food Sciences, Australia, noted that “the major problem associated with mycotoxin-contaminated animal feed is not acute disease episodes but low-level toxin ingestion that may cause an array of metabolic disturbances resulting in poor animal productivity.”

“With the globalization of feed ingredient trade and the rapid climate changes, the occurrence of mycotoxins become increasingly difficult to be predicted,” said Peng et al, 2018, Animal Nutrition Group, Wageningen Institute of Animal Sciences, Wageningen University, The Netherlands. “Thus, unnoticeable mycotoxin hazards can directly impact animal production systems. Preventing or minimizing mycotoxins in feed ingredients has become an important topic from the aspect of feed manufacturing industry.”

Dr. Alexandra Weaver of Alltech Mycotoxin Management said mycotoxins are a concern for feed quality and animal safety.

“The 2019 Alltech Global Feed Survey shows that, on average, finished feeds contain 6.3 mycotoxins,” she said. “More than 500 mycotoxins are identified that can cause a variety of negative effects in animals leading to poor health and lower productivity.”

Weaver said it is necessary for producers “to implement a comprehensive mycotoxin management program to minimize these risks.”

Anneliese Mueller, PhD, product management associate at BIOMIN, said mycotoxins are nearly ubiquitous in animal feed — deteriorating feed quality and jeopardizing animal health and performance.

“The majority of feedstuffs are contaminated by two or more mycotoxins,” she said. “The interactions between various toxins can be dangerous and are not considered in most regulations or guidelines. For feed producers, this means that vigilance and regular testing are required.”

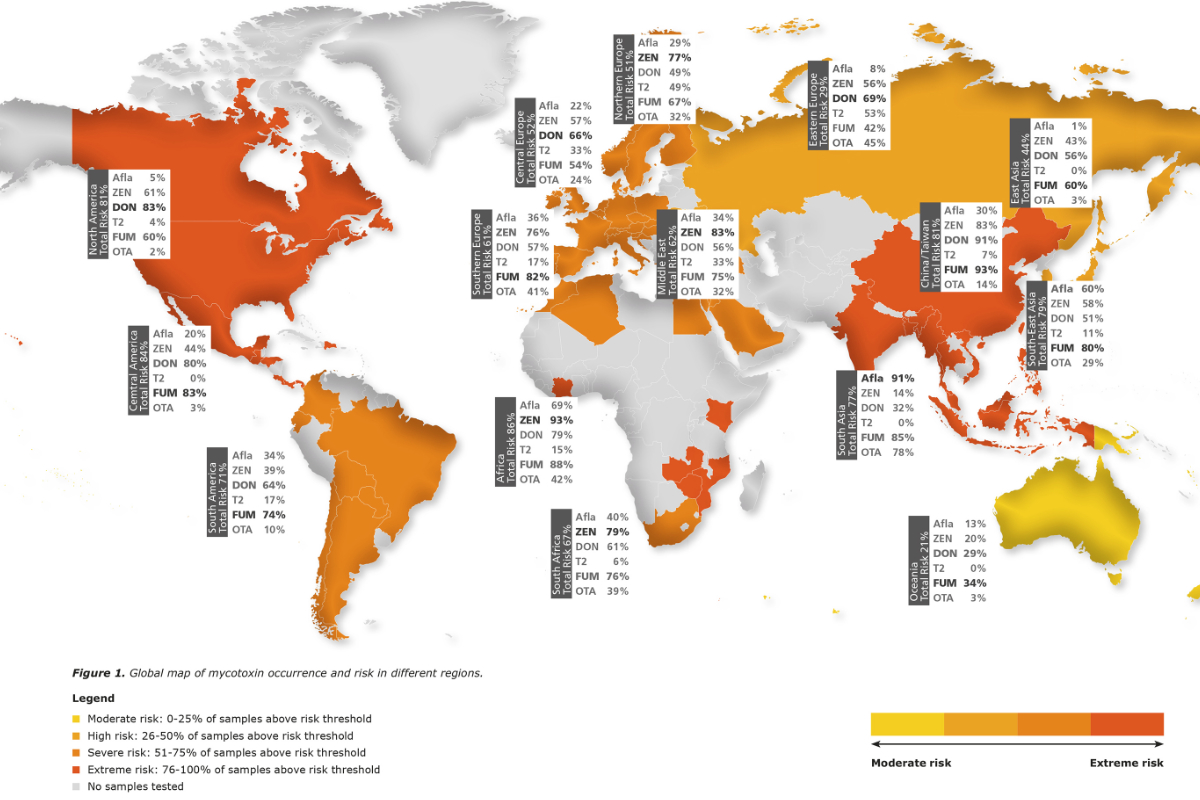

Mueller said the latest BIOMIN Mycotoxin Survey reports the occurrence of mycotoxins in 9,730 finished feed and raw commodities samples from 72 countries. It indicates a genuine threat in feed, depending on crop, toxin, region and species. Because the known mycotoxins cannot be completely removed by good agricultural practices, several distinct mitigation strategies are required: binding, biotransformation and bioprotection.

“Concern about rising levels of mycotoxins in feed grains has driven innovations for more reliable testing methods,” said Eugene Rodberg, senior product manager — feed quality, Kemin Animal Nutrition, and Health — North America. “With the right testing equipment, producers know in minutes if their grain is contaminated with performance- and profit-robbing mycotoxins. Once the types and levels of toxins are known, there are products producers can add to their feed to address the issue – including clays and zeolites, activated charcoal, yeast cells, biologics and enzymes. These compounds are not all equal, so it is important to identify a solution with demonstrated efficacy against the toxins you are facing.”

Animal feed experts have been studying how different levels of mycotoxins can produce synergistic effects on feed performance. Research has shown that different mycotoxins in a feed ration can have a greater total negative impact on animal performance in feed conversion, mortality, and fertility rates, said Pat Frasco, director of corporate accounts for Neogen.

“Maximizing feed performance is vital at a time of tight margins for livestock producers,” he said.

Frasco said that in addition to the major six mycotoxins (aflatoxin, DON, Fumonisin, OTA, T2-HT2, and Zearalenone), another group of toxins causing issues are ergot alkaloids.

“The incidence of ergot contamination has increased in places like Europe, Canada and the northern U.S. that raise small grains, especially rye,” he said. “Once ergot enters the feed stream, it is impossible to remove, so testing grain early is the most effective way to control.”

Enterprises processing grains for either human foods, pet foods, livestock production, and aquaculture must prevent the introduction of mycotoxin-contaminated grain from entering their production facilities at levels exceeding advised standards, said Jeff Gwirtz, PhD, a milling industry consultant, and president of JAG Services Inc.

“Where lower levels of mycotoxins are allowed into the facility, great care regarding processing impacts on both concentration and/or dilution of mycotoxins must be well known and documented,” he said.

Since ingredients may account for 70% to 90% of the cost of producing feeds, managing ingredient quality is important in ensuring high feed mill productivity, said Ryan Whipkey, product manager for life sciences, EnviroLogix.

Whipkey also advised that to control variation in feed ingredient quality, the feed mill must have a robust QA/QC policy that describes what, when and how to measure ingredient quality.

“On-site measurement of bulk ingredients at the point of delivery enables feed mills to segregate low-quality ingredients and appropriately re-formulate to produce finished feeds that meet requirements,” Whipkey noted.

He also said a best-in-class QA program should have an ingredient rejection policy that specifies the analytical values that trigger a rejection.

“Catching mycotoxin growth in early stages by constantly monitoring incoming grains and the storage of those grains will help to avoid higher costs and production problems down the road,” said Mark MacBeath, senior product manager in PerkinElmer’s Food sector.

Mycotoxin reducing strategies

There are many approaches that can be taken to minimize mycotoxin contamination in animal feeds, and these involve prevention of fungal growth and therefore mycotoxin formation, and strategies to reduce or eliminate mycotoxins from contaminated commodities, especially feed additives, Bryden said.

Peng et al, 2018, said the mycotoxin-reducing methods fall mainly into four methodologies: physical methods, thermal methods, chemical methods and mycotoxin-controlling feed additives.

They said the first three methodologies mainly focus on how to reduce mycotoxins in feed ingredients during processes, while the last one focuses on how to compensate the adverse impacts of mycotoxin-contaminated diets in animal bodies.

Zhu et al, 2016, Guelph Food Research Centre, Agriculture & Agri-Food Canada, found that “suggested strategies of decontamination include eliminating mycotoxins from contaminated grains, decreasing the bioavailability of such mycotoxins in the gastrointestinal tracts of animals, or directly degrading mycotoxins in feeds. Based on these points of action, a number of approaches such as adsorption, chemical treatment, and bio-transformation by catabolizing microorganisms/enzymes have been developed and optimized.”

Reducing risk during storage

Gwirtz said increased on-farm storage capacity raises the potential for commingling crops harvested in different years with varying mycotoxin levels, and the presence of living organisms can potentially increase mycotoxin levels in storage that are detrimental to both humans and livestock.

“Feed millers should consider implementing different strategies to effectively control mycotoxins on their grain,” advised Carlos A. Campabadal, PhD, International Grains Program Institute, Department of Grain Science and Industry, Kansas State University.

Campabadal said during storage, different grain quality management strategies should be utilized to reduce any potential increase in the grain’s temperature and moisture content that can trigger mycotoxin production. Among these strategies is the application of mold inhibitor, grain aeration, grain movement, reduction of internal condensation inside the storage structure (silo or warehouse), etc.

“It is important that the feeders on the animal farms get cleaned periodically to reduce any potential accumulation of old feed that can get moldy,” Campabadal said.

“Prevention methods, including pre-harvest field management and post-harvest storage management, are still the most effective strategies since mycotoxins are hard to be eliminated once they are present in the ingredients,” commented Peng et al, 2018.

Reducing risk for processing

Campabadal said if mycotoxins are present during feed processing or as a finished feed, the feed should be separated depending on its mycotoxin concentration. He added that in some cases higher levels of certain mycotoxins can be fed to bigger mature animals like beef cattle compared to other more susceptible animals like day-old chickens.

“It is possible in some instances to reduce the mycotoxin load of grain for further processing,” Gwirtz said. “Techniques include aggressive/intensive scouring to reduce mycotoxin presence at or near the surface of the grain. Intensive scouring may be less useful under conditions where fungus hyphae have deeply penetrated the grain. Specific gravity separation methods can be used to exclude or separate lower specific gravity kernels with severe fungal infections that may contain elevated toxin levels. Color sorting of grain may also aid in separating off-color contaminated grain from good material to be processed.

“The processor must have the ability to handle, store and sell grain with higher levels of contamination generated as a result of the selective separation. Where mycotoxin contamination is limited to the outer surface, processing systems are designed to separate the outer seed coat, or bran mycotoxins may be concentrated in the co-product feed. The endosperm and germ can be further separated and reduced into flour, semolina, meal, or grit with a significantly lowered mycotoxin level. Careful monitoring of the process is required as tests for mycotoxins do not tell us the location of the toxin contaminating the grain, which may change depending on growing, harvesting and storage conditions.”

Mycotoxin-reducing effects of other feed manufacturing technologies, like milling, dehulling and thermal methods, could be inconsistent and limited by various practical conditions. In addition, the evident reducing effects of some physical removal methods require the costs of high grain mass loss, which could be a dilemma from the aspect of practical manufacturing, reported Peng et al, 2018.

Feed additive solutions

Another strategy to control mycotoxins in feed is to add mycotoxin binder in the feed ingredient mixing process. They can help bind mycotoxins in the stomach of the animal to make them get excreted out of their digestive system, Campabadal said.

According to Vila-Donat, et al, 2018, Food Technology Department, University of Lleida, Spain, in 2009, the European Union (386/2009/EC) approved the use of mycotoxin-detoxifying agents, as additives to prevent mycotoxicoses in farm animals.

“There are no effective methods of decontaminating feed with mycotoxins, but the use of adsorbents is the only practical solution to feed decontamination,” they said. Vila-Donat et al, 2018, concluded: “adsorbents with multi-mycotoxin adsorption ability seems to be an effective solution.”

“The Mycofix product line of mycotoxin deactivating feed additives uses all three mitigation strategies to provide absolute protection against mycotoxins,” Mueller explained, adding, “Mycofix contains bentonite for the selective binding of adsorbable mycotoxins such as aflatoxins and ergot alkaloids. It also contains microorganisms and enzymes that transform trichothecenes, zearalenone, ochratoxin A, and fumonisins into non-toxic substances. Lastly, it contains a blend of plant and algae extracts for hepato- and immune-protection.”

Weaver said Alltech RAPIREAD comprises a system of tools, services and technologies to manage mycotoxin risk in feed and animal industries.

“Components of mycotoxin management include analysis by Alltech 37+ or rapid test kits, assessment of feed mill or farm quality control, and the use of the Mycosorb A+, which provides rapid and efficient mycotoxin mitigation for a broad range of mycotoxins,” she said.

For mycotoxin management in the feed industry in North America, “KALLSIL from Kemin is an enhanced zeolite-based mineral that provides broad-spectrum fungal metabolite control to improve feed quality and minimize performance declines due to mycotoxins — all with the minimal binding of vitamins and minerals,” Rodberg said.

He further explained, “Zeolite has an infinite 3-D, crystal structure that helps trap small molecules in its channels and pores. This sequestration reduces the intestinal absorption of harmful fungal metabolites and promotes improved performance.”

Peng et al, 2018, in their report said feed additive products specifically targeting mycotoxins are promising but still in their infancy, since the in vitro functioning of some products is inconsistent, and their in vivo functioning needs more proof.

Feed industry recommendations

Campabadal said the reduction or control of mycotoxins in feed should be an integrated approach from all areas involved in feed production (purchasing, nutrition, and feed manufacturing).

Zhu et al, 2016, reviewed recent patents on innovative technologies for the mitigation of mycotoxins in animal feed and ingredients and concluded that “a clear understanding of such novel detoxification methods and development-trends can be beneficial to the feed and livestock industry and will contribute to assuring pre- and post-harvest management and processing practices are in place that maximizes the consumers’ safety and profits of livestock and related industries.”

Mycotoxin prevention management and the processing stage of cleaning and sorting are still the most efficient strategies to control mycotoxin hazards in current feed manufacturing, concluded Peng et al, 2018, in their review on strategies to prevent and reduce mycotoxins for compound feed manufacturing.

“Not all feed raw materials are harvested or kept in ideal conditions,” said Stef De Smet, DVM, marketing manager — health, Kemin Animal Nutrition, and Health — EMENA. “The mycotoxin threat is a daily reality. Even when you do not see clear symptoms in your livestock, it can challenge the animal’s health, silently mortgaging animal performance and, by consequence, the economic benefit of animal production.”

Peng et al, 2018, added, “Prevention strategies are essential since it is impossible for other technologies to completely decontaminate the mycotoxin-contaminated feed samples once they are present.”

Feed safety is a prerequisite for food safety and human health, as well as a necessity for animal health and welfare. It is a component of access to trade, income generation, and economic sustainability. In addition, it contributes to feed and food security and decreases feed losses. Feed is an integral part of the food chain, and its safety has been recognized as a shared value and shared responsibility.

Therefore, feed production must be subject, in a similar manner as food production, to the quality assurance of integrated food safety systems. Given the direct links between animal feed and the safety of foods of animal origin, feed production and manufacture must be considered as an integral part of the food production chain.